[Nanografi] Cellulose Nanocrystal (Nanocrystalline Cellulose,CNC)

SKU:NG01NC0101

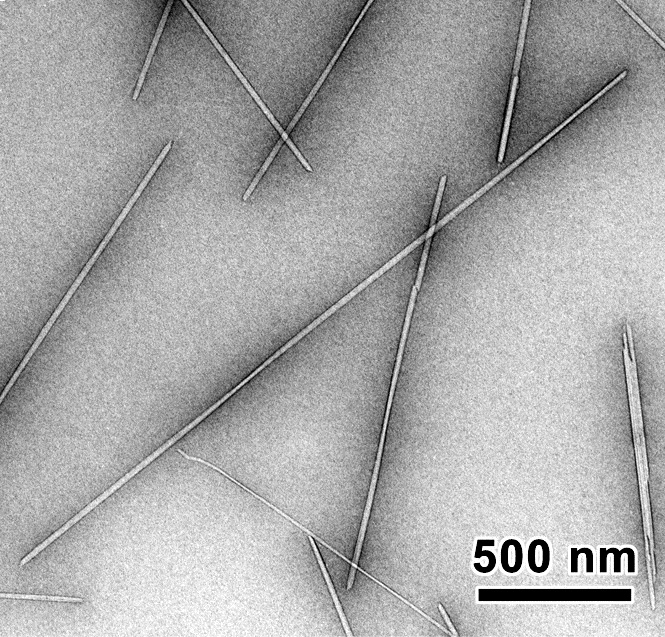

Wide: 10-20 nm, Length: 300-900 nm, Dry powder

Crystalline Nanocellulose is cellulose in crystalline form, composed of nanosized cellulose fibrils. These submicroscopic particles,

known as nanocellulose, have several features such as high strength, electro-magnetic response, large surface area, etc. There

is a wide range of CNC application in different fields. We are glad to provide Nanocrystalline Cellulose with low price and high quality.

Technical Properties:

| Appearance (Color) | White |

| Appearance (Form) | Dry powder (~4 wt.% moisture) |

| Average Particle Size | 10-20 nm wide, 300-900 nm length |

| Cellulose Crystallinity (XRD) | 92% |

| Decomposition Temperature of Crystalline Nanocellulose (TGA in N2) | 349 oC |

| Density | 1.49 g/cm3 |

Frequently Asked Questions About CNC

1) What method is used for the production of nanocrystals?

Nanocrystals are produced by sulfuric acid hydrolysis.

2) Are any binders used during production?

No, no binders are used during production.

3) With which chemical is the dispersion of cellulose nanocrystals made? water or ethanol or any other chemical?

Deionized water is the typical medium for dispersion. Tap water is usable but the CNC particle association will be higher. Aprotic solvents such as DMSO, DMF and ethylene glycol are usable, as are mixtures of water with alcohols.

4) Where is CNC extracted from?

Our CNC which is extracted from cellulose, the main building block of trees and plants, is a redispersible powder of uniform acyclic nanometric crystals.

5) Can the CNC product be customized for different applications?

Their size, shape, and charge lead to unique behavior in suspensions. The high chemical reactivity of the crystal surfaces, through hydroxyl and sulfate groups, makes CNC customizable for various applications. The heat stability of the crystals allows high-temperature applications up to 280°C.

6) What is the main chemical group present in the product?

The main chemical group that is present on cellulosic products, including our CNC, is hydroxyl (OH) groups (both secondary and primary). In addition, our CNC contains sulphate (half-ester) groups that are introduced during the acid hydrolysis process.

TEM Image of Crystaliline Nanocellulose CNC NG01NC0101

Applications:

1. Body Armor Applications

Crystal structure of nanocellulose is consisting from packed array of needle-like crystals. These crystal structures are incredibly

tough and their strength value is nearly eight times higher than stainless steel. Therefore, nanocellulose can be perfect building

material for the future body armor studies.

2. Flexible Batteries

Generally, separator parts inside batteries made up from thick and stiff material which cannot be used for bendable applications.

Instead of these materials, flexible and thin nanocellulose combined with graphene material, flexible battery as the one of the big

dream in electrical industry can be produced.

3. Flexible Screens

Nanocellulose is bendable, transparent, light and strong material therefore it can easily take place of the plastic or glass. In the future,

nanocellulose will be one of the best material for bendable screen studies.

4. Filters

Nanocellulose can be used to filter and purify many types of liquids such as purifying saltwater to be drinkable, trapping dangerous

chemicals in cigarette and filtering out blood cell during transfusion.

5. Absorbent Aerogels

When the nanocellulose are mixed with the aerogel foam, incredibly porous and adsorbent material can be obtained that could make strong

and light wound-dressing and tampons.

6. Fuel Efficient Cars

Nanocellulose can be obtained by algae and actually, this is quite cheap production method. Therefore, it will be possible to use it in serious

bulk materials. In the cars, components from stuff to interior trim will be produced from the light composites reinforced with nanocellulose.

By this way, decrease in the weight of the components will save the fuel consumption of the cars.

7. Biofuel

During the production of nanocellulose by algae, it is possible to obtain biofuel at the same time by changing the DNA of the helpful bugs.

Result of these process actually will not produce real nanocellulose material, but it will bring into useful byproduct.